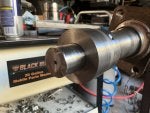

The axle is a 2003 out of a 2500HD with G80 differential. The complete carrier is in with the cover on. Hubs on, axles in. I used two scales to verify. The orange scale reads 323.5. blue scale reads 345.0

I did not weigh it complete with disc brakes. Wish I had.

![Image]()

![Image]()

I did not weigh it complete with disc brakes. Wish I had.