Well I have been a lurker forever on here and I was going to make a build thread later down the road but decided to just throw one up here tonight.

As the truck sits its a 91 with a 4.0l, m50d, 1350 doubler into 1354e case. 31 spline explorer axle with a detroit and a hp dana 44 with chromos and a yukon grizzly. Both axles have 4.56 gears and rolls on 37s.

I used James Duff early bronco radius arms, coils, buckets and trac bar bracket. Stupid easy SAS. The steering is all 1.5 DOM made from ruff stuff heavy duty parts.

I took the bed off and built a tube bed and installed a 22 gal fuel cell. The skins are just plastic for circle track cars.

The whole intention of my build has always been to drive to the trail/camping area/badass remote areas etc. and drive home. No tow rig for me.

Here are a bunch of random pics as the rig sits now. I wont post a bunch of old pics of the SAS and build up, if you want to see more I can direct you to them.

![Image]()

![Image]()

![Image]()

![Image]()

Now the next phase of my build. I am swapping in a 351w efi from a 89 Bronco. I am rebuilt the whole thing; dome pistons, xtreme 4x4 cam, roller tip rockers, lightning lower intake, expo. gt40 upper, high vol oil pump, ported heads etc. I am also converting from speed density to a maf setup using 93 mustang parts.

I have a rebuilt C4 I got from a member on here full of goodies, full manual reverse pattern, and a TCI torque converter.

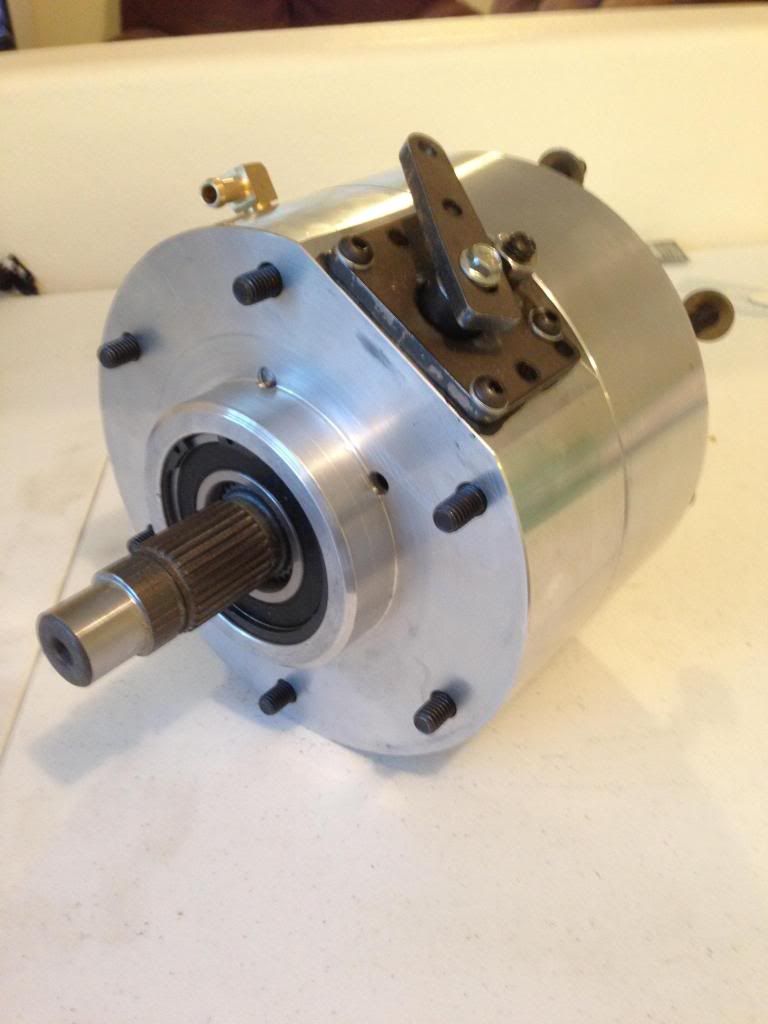

For transfer cases I am using a Behemoth drive train strong box, and a flipped dana 300 with a lot of behemoth parts. (should be getting this any day now) and triple cable shifters. I am going to upgrade the rear output for sure, and potentially the front (is this a necessity or can i get away with the stock front?)

![Image]()

![Image]()

![Image]()

![Image]()

Anyway that is where I am at right now. I know, no tech, but deal with it. Plans after the engine swap is work on a rear axle, leaning toward a 9 inch, and potentially links. Comments, questions and concerns will be appreciated.

As the truck sits its a 91 with a 4.0l, m50d, 1350 doubler into 1354e case. 31 spline explorer axle with a detroit and a hp dana 44 with chromos and a yukon grizzly. Both axles have 4.56 gears and rolls on 37s.

I used James Duff early bronco radius arms, coils, buckets and trac bar bracket. Stupid easy SAS. The steering is all 1.5 DOM made from ruff stuff heavy duty parts.

I took the bed off and built a tube bed and installed a 22 gal fuel cell. The skins are just plastic for circle track cars.

The whole intention of my build has always been to drive to the trail/camping area/badass remote areas etc. and drive home. No tow rig for me.

Here are a bunch of random pics as the rig sits now. I wont post a bunch of old pics of the SAS and build up, if you want to see more I can direct you to them.

Now the next phase of my build. I am swapping in a 351w efi from a 89 Bronco. I am rebuilt the whole thing; dome pistons, xtreme 4x4 cam, roller tip rockers, lightning lower intake, expo. gt40 upper, high vol oil pump, ported heads etc. I am also converting from speed density to a maf setup using 93 mustang parts.

I have a rebuilt C4 I got from a member on here full of goodies, full manual reverse pattern, and a TCI torque converter.

For transfer cases I am using a Behemoth drive train strong box, and a flipped dana 300 with a lot of behemoth parts. (should be getting this any day now) and triple cable shifters. I am going to upgrade the rear output for sure, and potentially the front (is this a necessity or can i get away with the stock front?)

Anyway that is where I am at right now. I know, no tech, but deal with it. Plans after the engine swap is work on a rear axle, leaning toward a 9 inch, and potentially links. Comments, questions and concerns will be appreciated.