My attention to detail and need for a good "Cherry Picker" got crossed up recently.

To begin I have to go back a couple years. Someone offered my dad a "FREE" Engine Hoist, he has a good one, but since he's a sucker for "FREE" he drags it home. It's a real pile! The roller bearings are out of every caster, so they won't spin unless you smack them with a hammer to get them to line up. The jack will only lift to horizontal and I had gone to wrapping the base with a rag because it leaked so much oil. But again it was "FREE". Dad more or less pawned it on to me, since I didnt own my own. My plan was to restore it but time flew and it got pressed into service more times than I'd like to count since it sucked so BAD.

Well in August last year it met its full demise at Bonneville. I drug it home and it sat outside until a few weeks ago, rusting and languishing.

Here is the monster rebuild and attention to detail upgrade of a Pile-O'Junk AC-Delco hoist from Oriellys.

New they are $299

http://www.oreillyauto.com/site/c/detail/ACD9/34132.oap

So I figured even if I spent a bit more than $300 redoing mine the way I want it, I'd be better off than buying a new one.

So first up. I bought a new Replacement jack from Oriellys $105.

http://www.oreillyauto.com/site/c/detail/ACD9/34133.oap

Here it is slightly after being torn down and modifications have begun. Note the dirt & oil around the jack mount and then down?

![Image]()

Next up casters, and an upgrade.

Ballbearing 6" bad mamajamma's, $72. These roll like silk even on uneven pavement or as I need on Salt and not sink in. Downside its much taller now so going under low vehicles it no beuno. I may build a new set of low rider legs for it though, we'll see.

![Image]()

I did break down the old casters and steal the old wheels, they are nice and worth saving.

![Image]()

Now with the wheel upgrade the mounts on the chassis were totally undersized. Bring on the new burned ones.

![Image]()

![Image]()

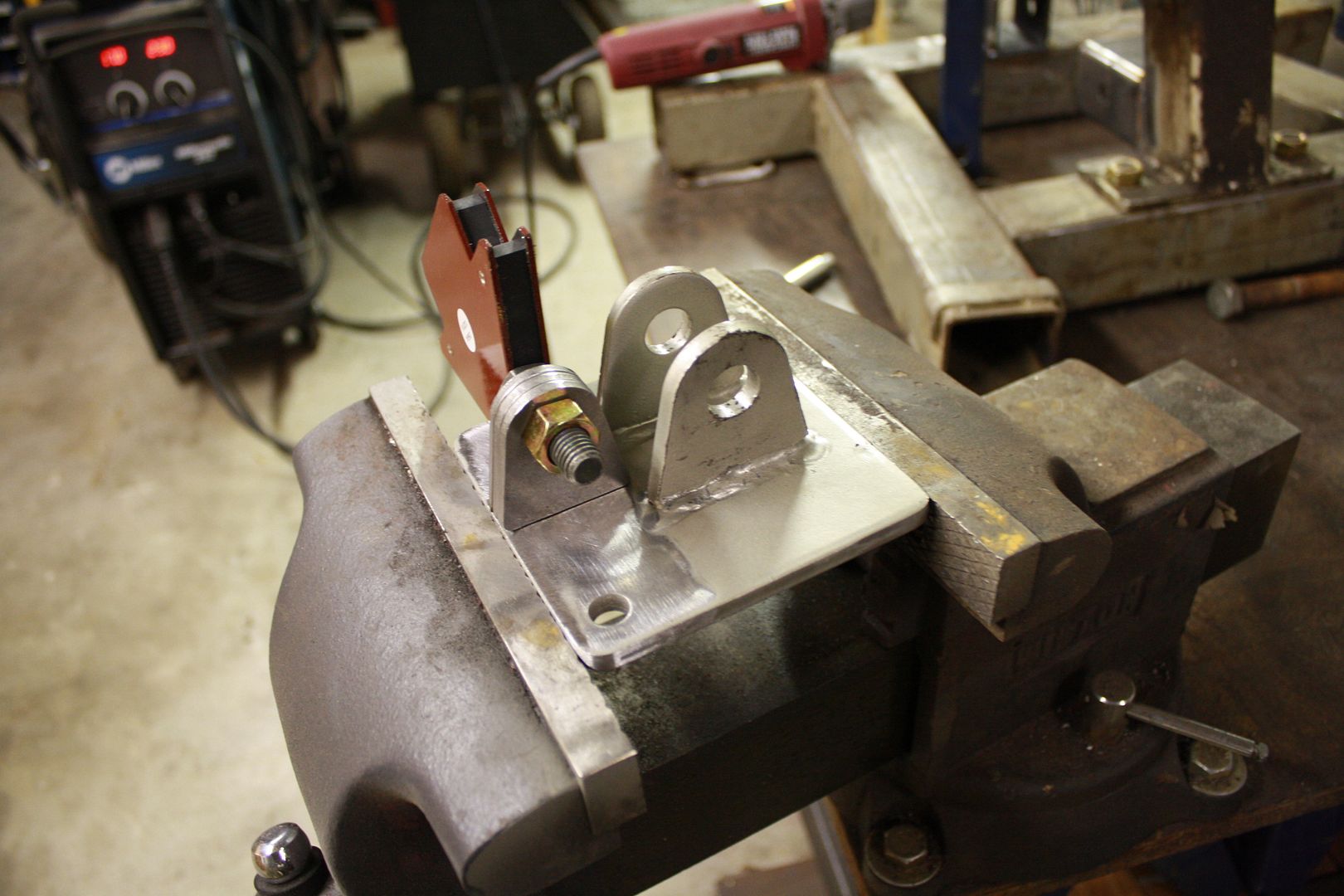

One thing this Hoist gets used for is to lift the nose of our SaltCar for loading and unloading off the trailer. Kind of a mini-towtruck boom. It has a 2" receiver and you'd hook and jack up to lift the car and could pull it out of the trailer with the truck. Well the old one was welded in place and made for a BITCH when packing the trailer and strapping it to the wall. (as a matter of fact it wiped out one of our Moon wheel covers last year, luckily Moon was pitted right next to us and we traded tool use for a new one) So the new version receiver is removable and stash able.

![Image]()

![Image]()

To begin I have to go back a couple years. Someone offered my dad a "FREE" Engine Hoist, he has a good one, but since he's a sucker for "FREE" he drags it home. It's a real pile! The roller bearings are out of every caster, so they won't spin unless you smack them with a hammer to get them to line up. The jack will only lift to horizontal and I had gone to wrapping the base with a rag because it leaked so much oil. But again it was "FREE". Dad more or less pawned it on to me, since I didnt own my own. My plan was to restore it but time flew and it got pressed into service more times than I'd like to count since it sucked so BAD.

Well in August last year it met its full demise at Bonneville. I drug it home and it sat outside until a few weeks ago, rusting and languishing.

Here is the monster rebuild and attention to detail upgrade of a Pile-O'Junk AC-Delco hoist from Oriellys.

New they are $299

http://www.oreillyauto.com/site/c/detail/ACD9/34132.oap

So I figured even if I spent a bit more than $300 redoing mine the way I want it, I'd be better off than buying a new one.

So first up. I bought a new Replacement jack from Oriellys $105.

http://www.oreillyauto.com/site/c/detail/ACD9/34133.oap

Here it is slightly after being torn down and modifications have begun. Note the dirt & oil around the jack mount and then down?

Next up casters, and an upgrade.

Ballbearing 6" bad mamajamma's, $72. These roll like silk even on uneven pavement or as I need on Salt and not sink in. Downside its much taller now so going under low vehicles it no beuno. I may build a new set of low rider legs for it though, we'll see.

I did break down the old casters and steal the old wheels, they are nice and worth saving.

Now with the wheel upgrade the mounts on the chassis were totally undersized. Bring on the new burned ones.

One thing this Hoist gets used for is to lift the nose of our SaltCar for loading and unloading off the trailer. Kind of a mini-towtruck boom. It has a 2" receiver and you'd hook and jack up to lift the car and could pull it out of the trailer with the truck. Well the old one was welded in place and made for a BITCH when packing the trailer and strapping it to the wall. (as a matter of fact it wiped out one of our Moon wheel covers last year, luckily Moon was pitted right next to us and we traded tool use for a new one) So the new version receiver is removable and stash able.